| Main Technical Parameters | |

|---|---|

| Machine Dimensions | 1200*1000*1750mm (L*W*H) |

| Attachment Range | 330*350*100mm |

| Attachment Efficiency | 1.0~1.5 S / PCS |

| Movement Method | ABB Robot |

| Conveying Method | Synchronous Belt |

| Conveying Drive Method | Stepper Motor |

| Width Adjustment Method | Manual |

| Positioning Method | Vision (COGNEX) |

| Positioning Accuracy | ± 0.02mm |

| Operating System | Windows |

| Control System | PC + Vision + Motion Control Card |

| Programming Method | Vision Coordinate Teaching |

| Operating Interface | 19-inch LCD + Keyboard + Mouse |

| Power Supply | 220VAC, 50HZ |

| Air Source | 0.5Mpa |

| Net Weight | 2600kg |

Installation effect

Keyword

Product Inquiry

Please leave your email, and our professionals will contact you as soon as possible!

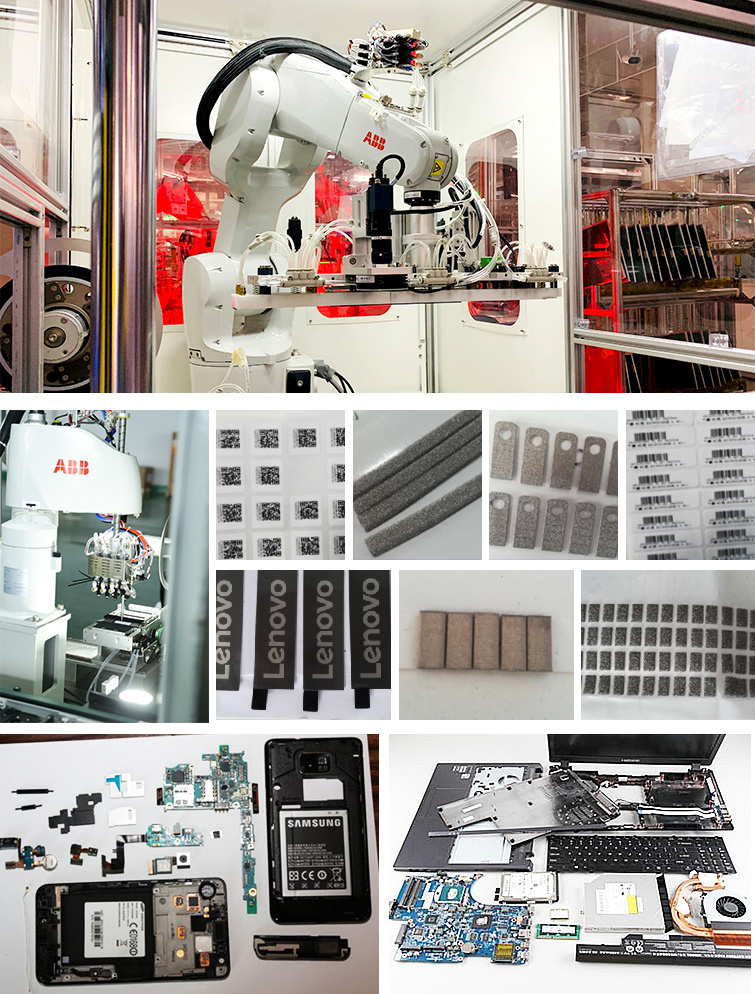

Fully automatic auxiliary material pasting equipment

By combining industrial robots with vision technology, it is possible to achieve compatibility with incoming material tolerances, high adhesion accuracy, high speed, and fully automated production without manual intervention.

The professional design of the peeling machine ensures the peeling effect of the materials, preventing sticking and slipping, and ensuring fast and stable peeling with on-the-fly auxiliary material replacement. At the same time, the peeling machine is compatible with different specifications of materials, has high compatibility, and can be used for peeling various materials. The entire line collects production process data in real time and interfaces with the customer's MES system, realizing the collection and storage of production process data and subsequent data analysis for process optimization.

Contact Information