| Main Technical Parameters | |

|---|---|

| Machine Dimensions | 600*1200*1750mm (L*W*H) |

| Material Feeding Method | Tray Feeding/Feeder Roll Feeding |

| Conveying Method | Fixture Return |

| Movement Method | TOYO Precision Module + Rotary Axis (Robot Mountable) |

| Axis Speed | X, Y: 0-4000mm/s. Z: 0-2000mm/s |

| Drive Method | Servo Motor/Multi-axis Control Card |

| Positioning Method | COGNEX Top and Bottom Camera Double Positioning |

| Positioning Accuracy | ± 0.03mm |

| Operating System | Windows |

| Control System | PC + Vision + Motion Control Card |

| Programming Method | Vision Coordinate Teaching |

| Operating Interface | 19-inch LCD + Keyboard + Mouse |

| Power Supply | 220VAC, 50HZ |

| Air Supply | 0.5Mpa |

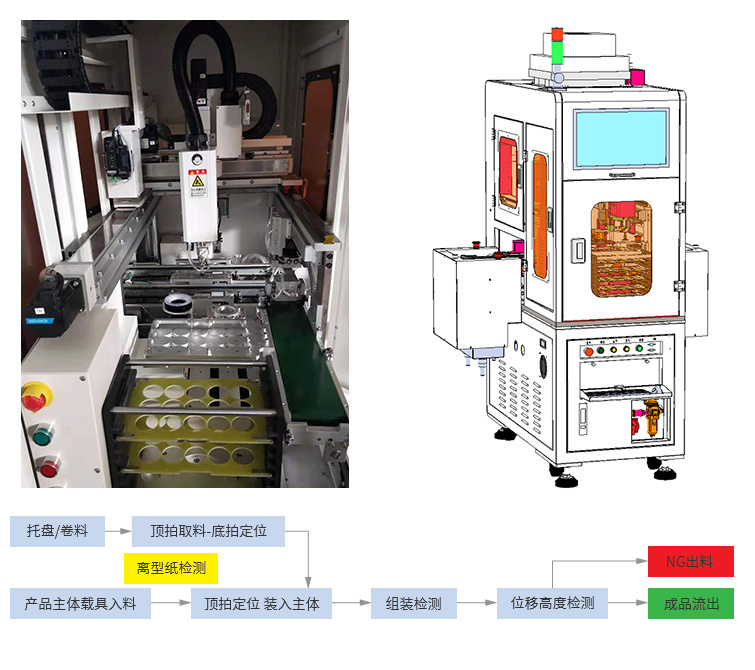

Installation effect

Keyword

Product Inquiry

Please leave your email, and our professionals will contact you as soon as possible!

Small precision mounting equipment

The main body of the equipment is 600mm wide. Suitable for precision assembly and mounting of materials such as mobile phone lenses, vibration motors, conductive cotton, foam, waterproof rubber rings, tamper-evident stickers, receivers, speakers, copper foil, heat dissipation silicon wafers, main boards, small boards, cameras, FPC, and batteries.

Universal tray or reel material can be freely switched. The equipment integrates upper and lower visual image acquisition and positioning and a precision module, with an assembly and mounting accuracy of ±0.03mm and a cycle time of 9S/PCS.

It adopts a dual-channel carrier up and down reflow method, with front and rear independent modular elevators. The equipment can operate independently or be connected to other equipment for production.

Contact Information

Category: